Factory Address

Near Municipal Workshop,

Aji Vasahat, Bhavnagar Road,

Rajkot - (360 003)

Gujrat - INDIA

Power Industries - Automotive Engine Parts Manufacturer & Exporters

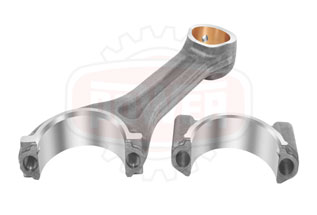

Connecting rods are utilized in various situations, most usually in the automobiles. Connecting rods connect the crankshaft to the pistons and are important for the perfect functioning of an internal combustion engine.

So Connecting Rod is a spinal cord and one of 5C component of the engine and we are the manufacturer of this most important part of engine. We at power industries forge the connecting rods and give it the strong built. If we talk about the range, there are various types of different engine application connecting rods we manufacture. We use steel alloy like 42CrMo4, C-70, EN8D, EN9, EN-15, SAE1141, and so on. Supported by industry experts, our product is fabricated with the best quality materials and cutting edge innovation.

Highly motivated engineers and technical experts with many years of experience and a trained eye monitor the quality of our products throughout the entire production process. Strict quality specifications and regular inspections guarantee the absolute reliability of our products.

" Power Industries has manufactured 300+ connecting rods for various engine applications. It has been tried, tested and trusted by our valueble clientele. "

Also we have most latest innovative fracture spilt technology of manufacturing connecting rod in-house which improve product quality and production efficiency and significantly reducing cost & energy. We can develop connecting rod as per customer’s specification and requirement by using state of the art machinery and our technical work force.

Production capacity: 1 million per annum (by 2 dedicated production lines of connecting rod)

Product range (In mm):

• Big End Bore Diameter: 30 to 125

• Small End Bore Diameter: 15 to 80

• Centre Distance: 75 to 350

Weight (In Kg): 0.5 to 15.00

Material:

• EN8D

• EN9

• EN15

• 42CrMo4

• C70

Fracture splitting connecting rods are not broken parts, just to be sure. This is the most latest engine design.

The manufacturing process of fracture-spliting connecting rods different compared to the traditional ones. The traditionally manufactured connecting rods lack in cap-to-rod fit, where fracture-splitting connecting rods allows precise, durable fit.

Types: